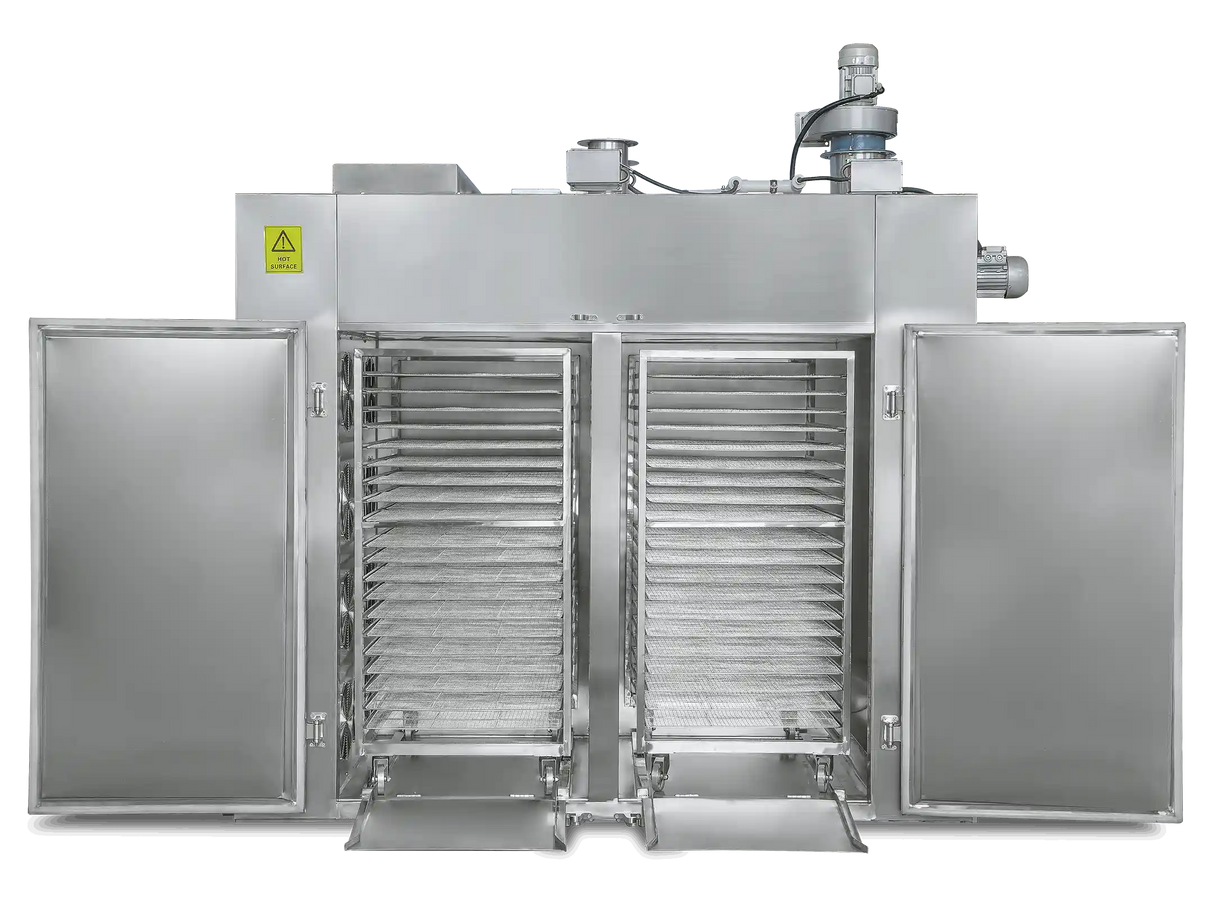

2 Trolley / 60 - 120 Tray / 17.7 - 35.3m² Total tray area

Our IU-02 Premium Industrial Dehydrator/Oven can be operated 24 hours a day, 7 days a week, 365 days a year! These dehydrators are customisable to suit your requirements.

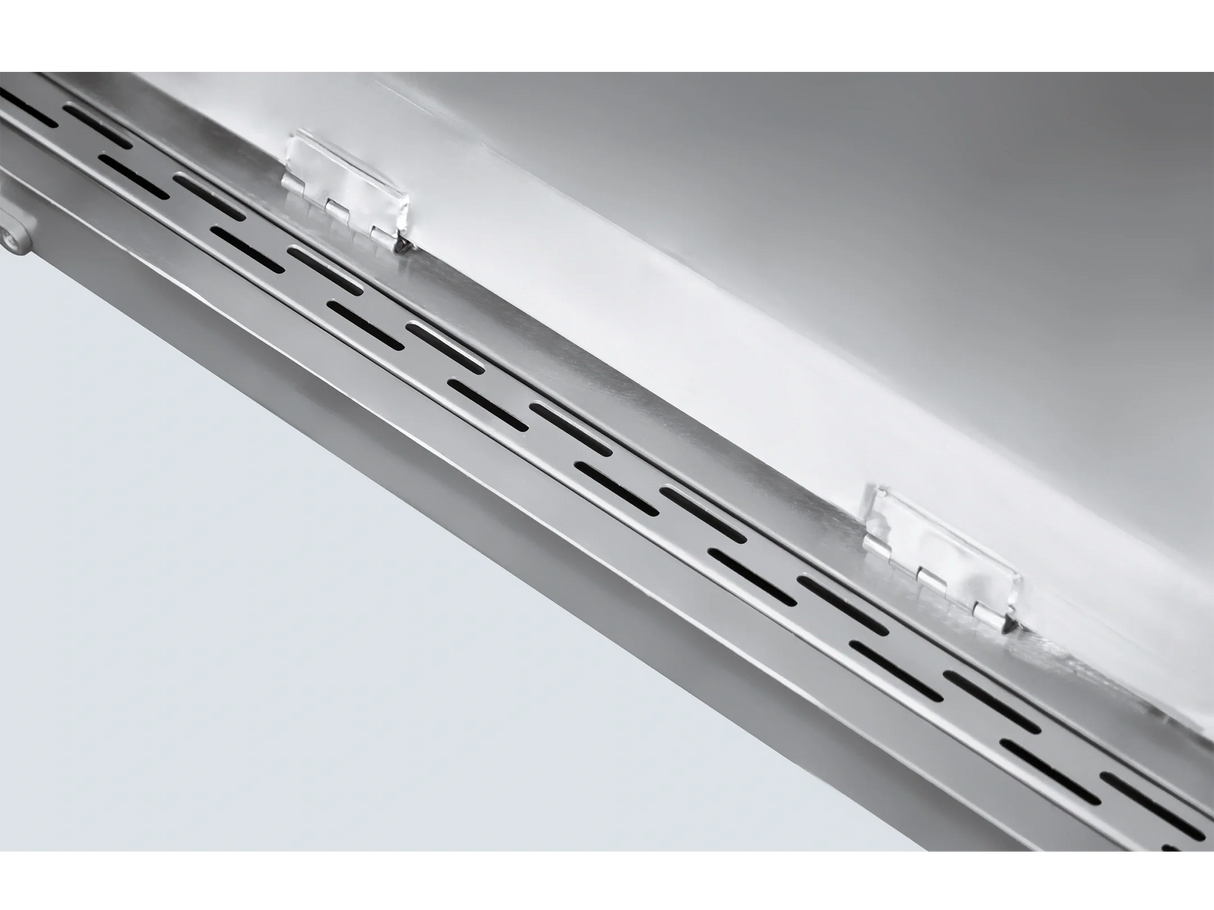

- The layer height for the carts can be modified to increase dehydrator capacity. This is done by reducing the gap between each layer allowing more trays per cart. Each layer of the cart holds two of our industrial trays (64 x 46cm) (e.g. A 15-layer cart holds 30 trays)

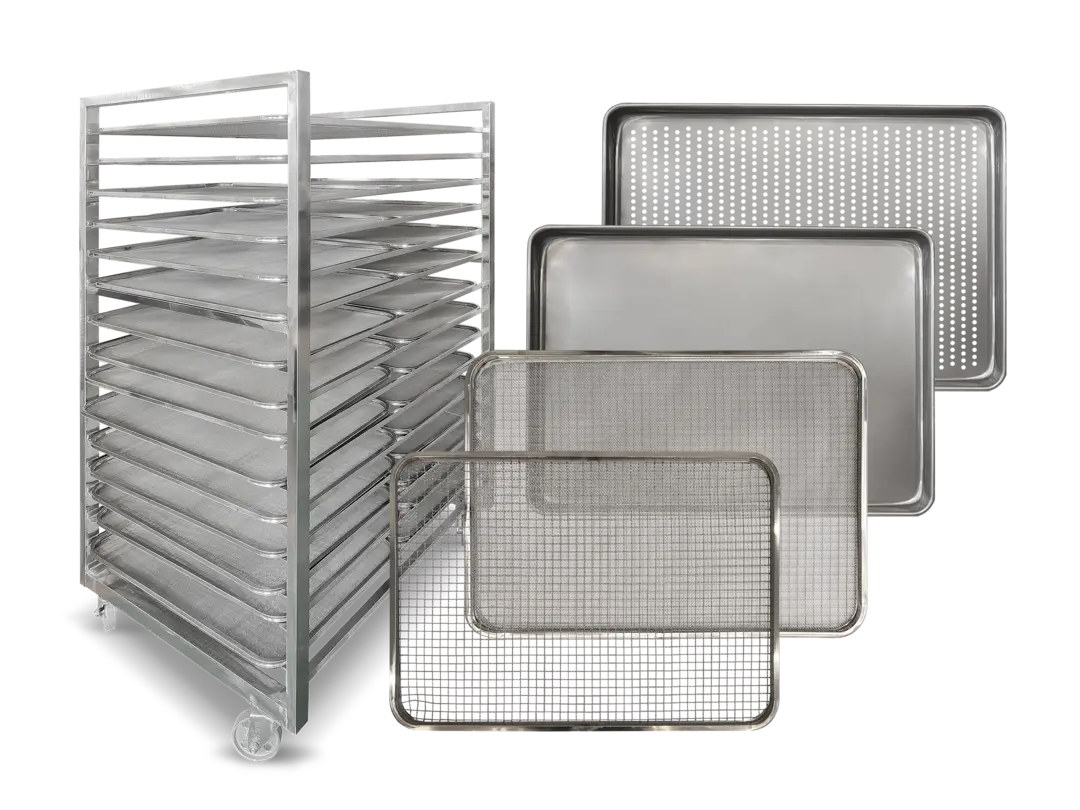

- There are 4 standard tray options for the Industrial range of dehydrators (304 Stainless Steel Pan, Perforated, Mesh, and Fine Mesh). Alternatively, contact an industrial specialist if you require custom-made trays for your industrial unit.

- This model has a temperature range from ambient - 120°C.

2 Trolley / 60 - 120 Tray / 17.7 - 35.3m² Total tray area

PLC Control Panel

SPECS & DOWNLOADS

| Model IU02 | STANDARD SPECIFICATIONS |

|---|---|

| Max Power Usage | 16.15 kW |

| Avg Power Usage | 6-7 kW |

| Voltage / Frequency | 3-Phase / 50-60Hz - 400V, Custom |

| Product Dimensions (W x H x D) | 2200 x 2000 x 1200 mm |

| Loading Footprint Required (W x H x D) | 2200 x 2000 x 2600 mm |

| Machine Weight | 750kg |

| Number of Exhaust Fans | 1 |

| Exhaust Air Volume | 850 m³/hr (per exhaust fan) |

| Static Pressure Rating | 1020 pa (per exhaust fan) |

| Internal Airflow | 6800 m³/hr |

| Temperature Range | Ambient to 120°C |

| Total Trolleys | 2 |

| Trolley Dimensions (W x H x D) | 920 x 1450 x 695 mm |

| Space Between Trays | 40 - 80 mm |

| Total Trays | 60 - 120 trays |

| Tray Dimensions | 460 x 640 mm |

| Total Tray Area | 17.7 - 35.3 m² |

| Timer | 0 - 9999 Hours |

| Material | Double walled industrial-grade 304 stainless steel. Insulated with high density aluminium silicate cotton. |

TROLLEY OPTIONS & SPECS

| Model | IDUTC-15 |

| Dimensions (W x H x D) | 920 x 1450 x 695 mm |

| Layers | 15 |

| Layer Spacing | 80 mm |

| Number of Trays | 30 |

| Tray area | 8.8 m2 |

| Model | IDUTC-18 |

| Dimensions (W x H x D) | 920 x 1450 x 695 mm |

| Layers | 18 |

| Layer Spacing | 67 mm |

| Number of Trays | 36 |

| Tray area | 10.6 m2 |

| Model | IDUTC-20 |

| Dimensions (W x H x D) | 920 x 1450 x 695 mm |

| Layers | 20 |

| Layer Spacing | 60 mm |

| Number of Trays | 40 |

| Tray area | 11.8 m2 |

| Model | IDUTC-25 |

| Dimensions (W x H x D) | 920 x 1450 x 695 mm |

| Layers | 25 |

| Layer Spacing | 48 mm |

| Number of Trays | 50 |

| Tray area | 14.7 m2 |

| Model | IDUTC-30 |

| Dimensions (W x H x D) | 920 x 1450 x 695 mm |

| Layers | 30 |

| Layer Spacing | 40 mm |

| Number of Trays | 60 |

| Tray area | 17.7 m2 |

TRAY TYPES & SPECS

| Model | IDUT-MT |

| Dimensions (W x H x D) | 46 x 64 x 1cm |

| Mesh spacing | 12 x 12mm |

| Tray area | 0.3 m2 |

| Model | IDUT-FMT |

| Dimensions (W x H x D) | 46 x 64 x 1cm |

| Mesh spacing | 2 x 2mm |

| Tray area | 0.3 m2 |

| Model | IDUT-FPT |

| Dimensions (W x H x D) | 46 x 64 cm x (2.5-4.5cm) |

| Mesh spacing | 15 |

| Tray area | 0.3 m2 |

| Model | IDUT-PPT |

| Dimensions (W x H x D) | 46 x 64 cm x (2.5-4.5cm) |

| Mesh spacing | 8mm Ø |

| Tray area | 0.3 m2 |

TECH FEATURES

MACHINE HIGHLIGHTS

A dehydrator does more than process food; it’s a statement of your brand’s values. Here’s how this aligns with consumer interests:

QUICK, SAFE, SECURE & FREE DELIVERY

Shipping Insurance Is Also Available On All Orders In The Checkout Page

-

Commercial Warranty

1. WHAT DOES THIS WARRANTY COVER?

It covers defects in material or workmanship under normal use. We will repair or replace products/parts that prove defective during the warranty period.

2. WHAT WILL WE DO TO CORRECT PROBLEMS?

We will action 1 of 3 scenarios based on the defect and the product purchased;- Send a brand-new replacement of the defective product. *Does not apply for industrial orders

- If the defective part of the product is already identified, we will ship the replacement part and have a service technician come onsite to replace and install once it has arrived.

- Send out a service technician to investigate the defect. Once the issue has been identified, the technician will either fix the defect immediately or notify us of replacement parts needed. If the latter, we will ship the required replacement parts to the service address. The technician will then return onsite to service and fix the product.

*If there is no technician locally available, then a local appliance repair technician can be sourced by the customer and BenchFoods will pay the technician invoice or reimburse the customer if prepaid.

3. HOW LONG DOES THE COVERAGE LAST?

The Warranty Period is now 5 years from the original date of purchase for Industrial, Commercial, and Domestic Dehydrators. Replacement products or parts, provided through a warranty claim, assume the remaining warranty of the original product or 180 days from the replacement or repair date, whichever is longer. *Spare Parts purchased outside of a warranty claim are not eligible for warranty coverage.Further information can be found on our warranty page.

-

Shipping & Returns

Shipping: Standard domestic shipping is included in your Industrial Unit price. These units are made to order and will take around 12-16 weeks to your door.

Returns: As these units are built to order and often have specific modifications to an individual customer, returns are not accepted unless due to manufacturing issues that are unable to be resolved from a technician servicing. -

Frequently Asked Questions

How much does shipping cost?

Standard domestic shipping is included in your Industrial Unit price.

How long does shipping take?

These units are made to order and will take around 10-12 weeks to your door.

Do you deliver internationally?

Yes, we deliver internationally and have regional distribution warehouses located across the globe. Because of our global operation, we get inexpensive international shipping rates. In some countries, we can deliver all the way to the end-delivery address. Others, we may only be able to deliver to customs. To request a shipping quote, please visit our contact us form or send us an email with the product you are interested in and the end delivery address.

Does the unit include trays?

Yes all of our dehydrators come with 304 food-grade stainless steel trays as well as a stainless steel drip tray at the bottom of each trolley. We offer 4 different types of trays, tray selection does not affect price. Additional trolleys and trays may be purchased on top of this. You may also purchase non-stick mats if desired.

Industrial units include 30 trays per trolley by default. Units can be modified to fit more trays per trolley dependent on the thickness of your product.How much can I dehydrate in this unit?

Contact one of our industrial specialists and we'll be more than happy to help you figure this out.